Expert in Laser Cutting Stamping Aeronautical Welding Mechanical Welding Boilerworking Folding Machining Penetrant Testing

Schligler, Expert in Boiler & Sheet metal working

Since 1856, Schligler design and manufacture metallic parts, sub-assemblies and assemblies with high added value for demanding business lines. Expert in boilerworking and sheet metal working, we deal with all traditionnal metallic materials (such as stainless steel, aluminum, steel) as for technical metallic materials (such as titanium, hastelloy, inconel). We work with thicknesses varying from 80µm to 12mm. Our expertise in laser cutting, stamping, bending, welding and boilermaking processes enables us to produce technical parts. Our entire team is available to help you in the manufacturing of parts.

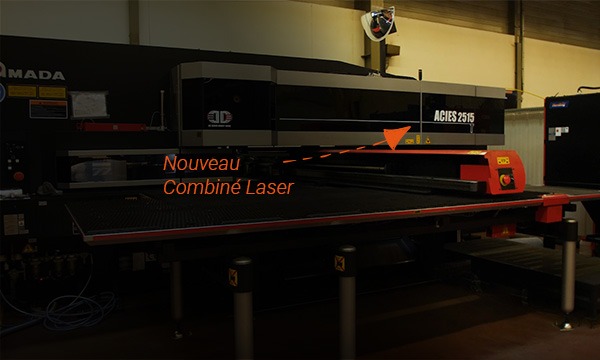

Means of production

We have significant resources. Our human resources and machine park enable us to manufacture both small and medium batches. With premises of over 6,000m2 in France and 2,200m2 in Tunisia, we are able answer and support every request. We haveon-hand all handling equipment as well as logistical means needed to ship your parts in the best conditions. Do not hesitate to get in touch with us to visit our facilities and discover our know-how.

Design Office

Our design office department will finely manage all your projects. It allows us to bring an outside view as well as our manufacturer’s point of view on your assemblies, sub-assemblies or parts to be made. In a co-engineering approach, we support you throughout the entire process, from prototyping to series production.

Common Values

All of our employees share common values. These values lead us and empowering us to move forward. We try to improve ourselves every day basing on policy that gather economy, social and ecology.

- Quality

- Performance

- Human

- Innovation

Some figures about Schligler

Certifications

In our company, quality is essential. That is why we value so much our various certifications. They are proof of our commitment and our efforts regarding the manufacture of our parts. We are ISO 9001 certified as well as NADCAP for NDT-Penetrant Testing.

Certification ISO 14001 & ISO 45001

We are taking the ISO 14001 certification which regards the environmental management system of our business. This standard enables Schligler, and its external different stakeholders, to ensure that the environmental impact is the main subject of concrete measures and improvements within the company itself. In addition, the ISO 45001 certification, which deals with employees safety and work conditions.

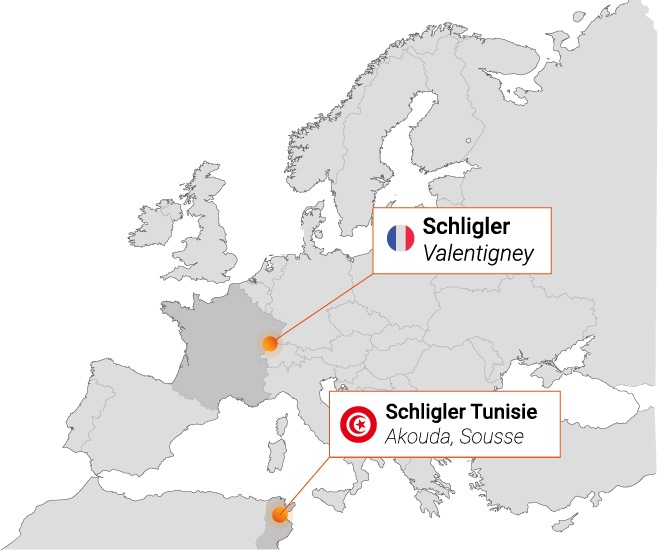

Between France & Tunisia

The main Schligler’s facility is located in Bourgogne Franche-Comté, more precisely in Valentigney. It is also known as the headquarters of our activity. In a context of globalization, in 2004, we launched our first subsidiary in Tunisia. This international structure procures advantage, because it enables us a better workload management while offering a interesting alternative to all our partners.

Some of our key partners

Last News

Find the latest information and highlights of the company.

As part of the renewal of the NADCAP certification, Schligler is proud to announce that …

In order to modernize our facilities and strenghten our know-how in welding area, we are …

As part of the renewal of the NADCAP certification, Schligler is proud to announce that …

In order to modernize our facilities and strenghten our know-how in welding area, we are …